Today, with the rapid penetration of intelligent healthcare, the equipment management in hospitals has long left behind the traditional mode of "manual inventory and experience-based judgment". Medical equipment, as the core carrier of medical services, its positioning accuracy, state controllability, and energy efficiency optimization directly affect the operational efficiency, medical quality, and economic benefits of the hospital. Angke Information Technology (Shanghai) Co., Ltd. has been deeply engaged in the medical Internet of Things field for over 20 years. With the "One Network Unlimited ® All-Network Data Distribution Platform" at its core, it has created a full-cycle management solution for medical equipment that integrates asset positioning, status monitoring, and energy efficiency control. It uses technological innovation to solve the pain points of hospital equipment management and leads a new paradigm of smart medical management.

Precise positioning enables assets to be "visible, accessible, and manageable"

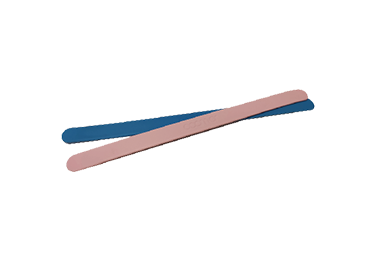

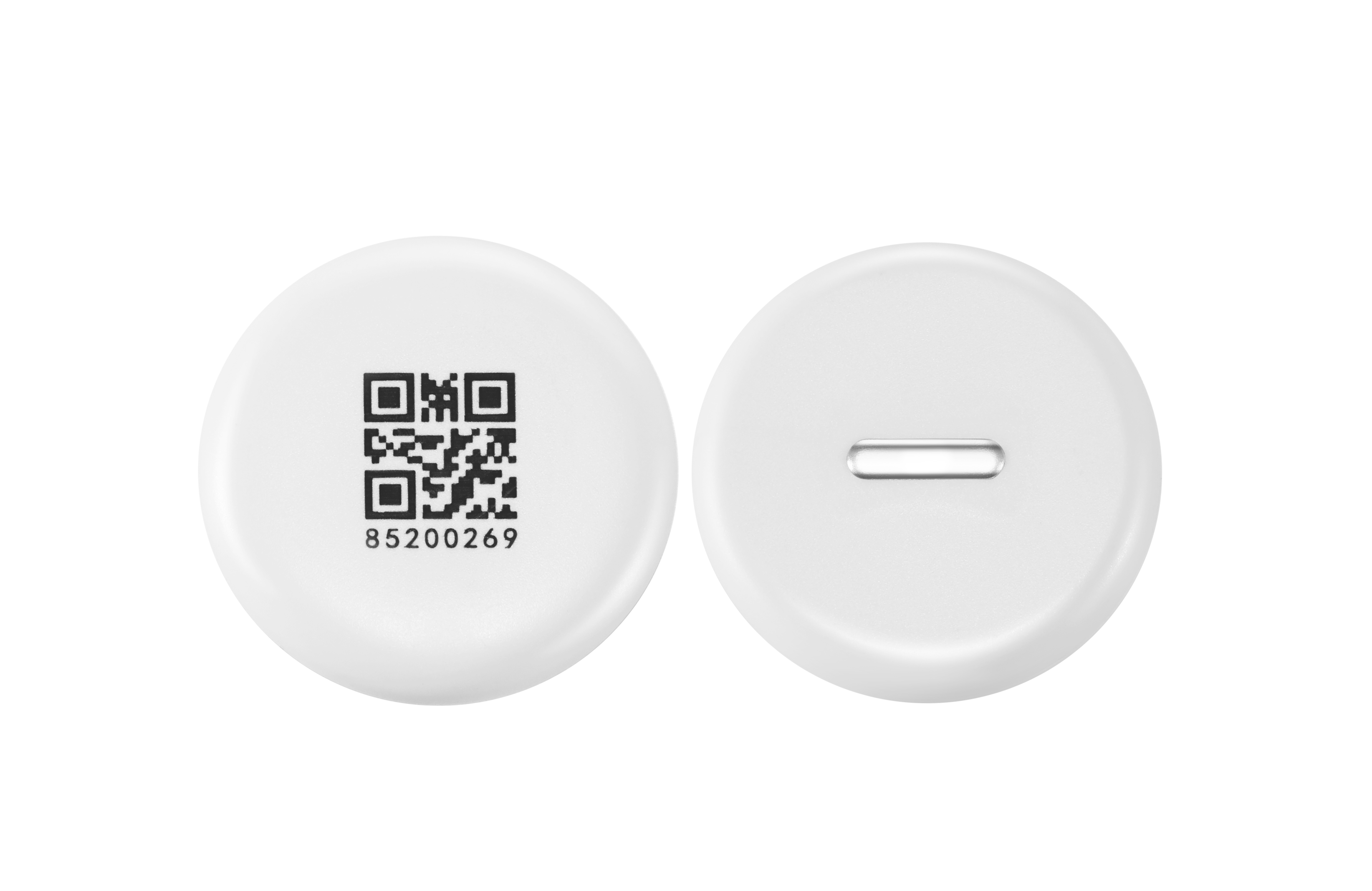

The hospital has a wide variety of equipment that is frequently moved. "Difficult to locate equipment, long inventory process, and easy loss" are long-standing pain points for clinical departments and logistics management. The Angke Asset Positioning Management System, leveraging room-level high-precision positioning technology, provides full-process visual management for movable equipment within the hospital. Whether it's the monitoring devices in the wards, the emergency equipment in the emergency department, or the precision instruments in the operating room, through UHF + LF + IR or BLE + LF + IR dual-mode asset positioning tags, real-time location tracking and movement trajectory traceability can be achieved.

Label pick up for 3 to 5 years long life battery (change), 120 months stable operation without frequent maintenance, more have illegally dismantle the alarm function, abnormal once the label is removed or device is removed to the prescribed scope, system will be calculated by window, text messages, E-mail and other multi-channel real-time early warning, and linkage security video automatically obtain the scene, Help administrators quick surveys to misappropriate situation, from the source to eliminate equipment loss. Combined with the "one-click inventory" function, the efficiency of equipment handover and regular inventory has been significantly improved, making the department shift more convenient, asset statistics more accurate, and completely eliminating the management predicament of "account and reality not matching".

Real-time monitoring enables "perceptibility, controllability and traceability" of the status.

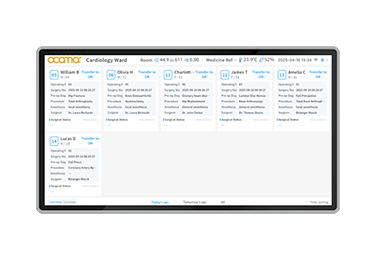

The on-board status, running duration and idle situation of medical equipment directly affect the rationality of resource allocation. The Onko equipment status management system, as the "perception nerve" of the entire cycle management, through high-performance status sensing tags, captures core status data such as equipment startup and shutdown in real time. Combined with the asset location management system, it realizes dual control of "location + status".

The label adopts BLE communication technology. It is small in size (length 50mm × width 50mm × height 10mm), and can be easily installed by using 3M adhesive. It is compatible with various medical equipment scenarios. With an ultra-long battery life of 36 months and an active removal alarm function, it ensures uninterrupted monitoring and safety guarantee. The system background automatically records data such as the working status, usage frequency, and idle duration of the equipment, generating a visual analysis report. This enables managers to clearly understand the "busy level" of each device, providing data support for equipment allocation and department configuration optimization - avoiding the problem of resource mismatch caused by shortage of popular equipment and waste of idle equipment, and ensuring that medical resources are precisely allocated to clinical needs.

Energy efficiency optimization enables costs to be "clearly calculated, significantly reduced, and well utilized".

The energy consumption costs generated by the long-term operation of medical equipment, as well as the resource waste caused by idle equipment, are important issues in hospital cost control. The energy efficiency management system of Angke equipment relies on Internet of Things sensing technology and current detection technology to conduct real-time energy monitoring of various medical equipment, comprehensively capturing the energy consumption data during equipment startup, shutdown, and operation.

The system presents core indicators such as equipment utilization rate, idle rate, and energy consumption curve in a graphical interface, making it easy for managers to identify "high-energy-consuming idle equipment" and "inefficient operating equipment" through data analysis. They can then optimize the equipment usage process and procurement configuration strategies accordingly. Through this system, hospitals can effectively avoid energy waste, prevent leakage and loss, and reduce unnecessary maintenance and repair expenses - saving considerable costs annually and significantly improving the input-output ratio, achieving the dual goals of "cost reduction and efficiency improvement" and "green operation".

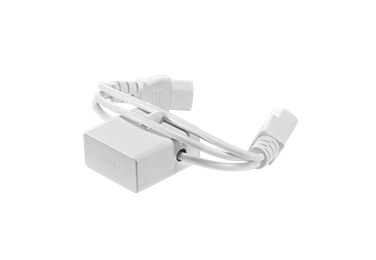

The platform is interconnected to form a "ecological closed loop" for the entire cycle management.

The three systems do not operate independently but are deeply coordinated based on the "One Network, Unlimited Connectivity, All-Connected Data, and Platform" of Angke, forming a "location tracking - status monitoring - energy efficiency analysis - decision support" full-cycle management closed loop. The platform has medical-grade reliability, stability, and security, supports multiple wireless communication protocols, and can seamlessly connect with hospital core systems such as HIS, EMR, and HRP, achieving data interoperability and resource sharing.

From the initial label binding during the equipment procurement and warehousing process, to the real-time positioning tracking and dynamic status monitoring in the clinical environment, to the precise energy consumption analysis and forward-looking maintenance and repair prompts in the operation and maintenance management, and finally to the standardized scrapping management after the equipment's expiration - the Angke Medical Equipment Full-Cycle Management System precisely records every key data of the equipment's entire life cycle. Relying on these visual and traceable core data, hospitals can accurately assess the equipment's usage efficiency, scientifically estimate the maintenance cycle, and reasonably optimize the procurement budget, truly promoting the upgrade of equipment management from the traditional "passive response" to the modern "active anticipation".

With over 20 years of technological accumulation and 1000+ successful cases as evidence, Angke has always adhered to the philosophy of "customer first, technology foremost". With the technical advantages of "multi-purpose in one network, multiple networks integrated into one", Angke continuously improves the full-cycle management solution for medical equipment. In the future, Angke will continue to deeply explore the field of medical Internet of Things, integrating cutting-edge technologies such as 5G and AI, making medical equipment management more intelligent, efficient and economical. It will inject continuous technological power into the construction of smart hospitals, helping hospitals achieve high-quality operations and providing patients with better medical services.